供应胶辊、玻璃辊、压花辊专用喷砂机厂家批发价格

技 术 参 数

喷砂部份外形尺寸:Φ600×1434

回收部份外形尺寸:长1700×宽700×高2000

电源:三相380V,50Hz

功率:5.5-8kw

工作压力:0.6-0.7MPa

磨料种类:金刚砂、棕刚玉、铜矿渣、塑料丸等

表面处理等级:Sa2.5-3

耗气量:2.2-6m3/min

磨料粒度:小于2mm

喷砂效率:10-15m2/h

重量:喷砂部份(以Φ600的罐体为例)227kg,回收部份150kg

磨料容积(取决于喷砂部份罐体的直径):

| 罐径(mm) | 600 | 700 | 800 | 900 | 1000 | 因为物料密度有差异,装料量数据供参考 | |

| 容积(m 3 ) | 0.18 | 0.3 | 0.46 | 0.63 | 1 | ||

| 装料量 kg | 棕刚玉 | 351 | 585 | 897 | 1229 | 2458 | |

| 碳化硅 | 300 | 500 | 760 | 1046 | 2092 | ||

| 钢丸(砂) | 801 | 1335 | 2047 | 2800 | 5600 | ||

| 石英砂 | 306 | 475 | 629 | 850 | 1700 | ||

易损件清单

| 序号 | 图号 | 名称 | 备注 | 正常使用时间 |

| 3 | T02.L06 | 密封圈 |

| 3000—4000小时 |

| 14 | T02.B04 | 喷砂管 | 内径1",10m | 2500—3000小时 |

| 15 |

| 回收管 | 内径Φ50 | 2500—3000小时 |

| 24 |

| 滤芯 |

| 6个月—1年 |

| 25 | T02.L03.03 | 耐磨衬套 |

| 2000—3000小时 |

| 26 | T02.L03.05 | 阀套 |

| 2000—3000小时 |

| 28 | T02.L02.04 | 小膜片 |

| 3000—4000小时 |

| 29 | T02.L02.05 | 大膜片 |

| 3000—4000小时 |

| 32 | 70-02 | 喷嘴 | 碳化硼 | 800—1200小时 |

| 34 | 70-08 | 护套 |

| 3000—4000小时 |

| 35 | 70-10 | 连接套 |

| 5000—10000小时 |

| 36 | 70-11 | 毛刷 |

| 80—120小时 |

注:部分备件根据具体使用情况更换,不同磨料对于使用情况有所影响,备件除磨损到不可使用需要更换,使用时间可部分延长。

产品用途及特性

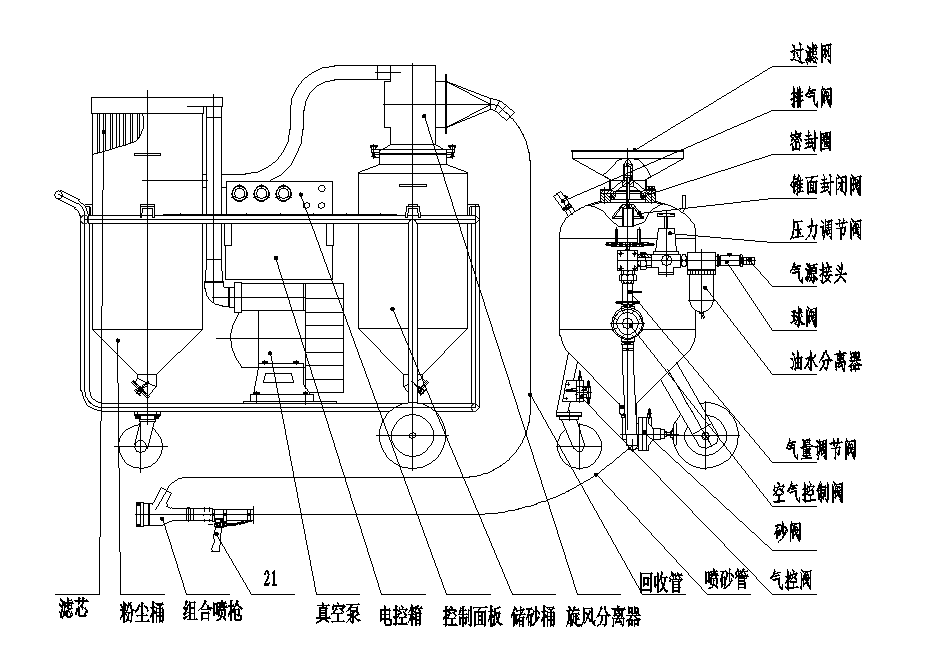

HXP-F系列分体式回收循环喷砂机为我公司设计的新型回收环保型喷砂机,广泛应用于机械、船舶、桥梁、铁路、石油管道、锅炉和港口建设等行业的钢结构表面除锈、表面强化;也可用于金属、玻璃、石材等的表面雕刻、喷花装饰性处理。如果配上内壁喷砂器,就可以对管道内壁进行喷砂处理。单独使用也可用作工业吸尘器。

分体式回收循环喷砂机分为喷砂部份和回收部份,与传统型回收循环喷砂机相比,它的最大特点是可以一机多用。当环保要求严格时,它可以做为回收循环式喷砂机使用;而没有环保要求,并且工人有防护措施时,则可将喷砂部份单独用作开放式喷砂机,以提高工作效率,喷砂完后,再用磨料回收部份--砂尘分离器清扫工作现场,回收散落的磨料,也可以在工地某处开放式喷砂,而同时在另一处使用砂尘分离器吸砂。所以如果用户购买一台分体式回收循环喷砂机,他就同时拥有了回收循环喷砂机、开放式喷砂机和砂尘分离器三种设备。

由于这种机型有独立的喷砂部份,因此它的磨料容量大大提高,并且![]()

![]() 有不同罐径可选。

有不同罐径可选。

它还有独特的磨料、粉尘分离装置。并且可以调节磨料和粉尘的分离等级。当选用不同直径或密度的磨料时,所产生的粉尘颗粒的大小和密度也是不一样的。通过调节分离器,可以准确地将磨料和粉尘分离开来,不会将磨料当作粉尘带走,也不会将粉尘当作磨料留下来。

售 后 服 务

1.我公司所有产品保修期为两年(易损件除外),自验收合格之日起计算。质保期内,买方应按卖方提供的随机文件的规定使用和设备保养。

2. 卖方在产品验收培训期间无偿为买方培训1-2 名操作及维修人员,并无偿为买方提供电话技术咨询服务。

3. 卖方对其设备进行终身维护,超过保质期限的设备,卖方收取相应的维修费用。

4. 质保期内如有零部件损坏,自更换该零部件起,再对该零件重新计算质保期在质保期内,非因买方使用不当原因损坏的电器元部件,卖方无偿提供设备维护和更换零部件(易损件除外),接到买方通知后4小时给予答复,24小时内到现场,48小时内解决问题。

5. 质保期内售后服务由卖方免费负责。卖方自接到服务通知始24 小时内给买方作出书面响应;对买方不能自行解决的问题卖方工程师应在3个工作日内到用户现场进行维修。

6. 对质保期外买方的维修人员无法自行排除的设备故障,卖方工程师须提供免费电话、传真解答。卖方应对该设备的配置和制造质量负责,整机应符合相关的制造标准和安全.环保要求。

7. 配件的订购。我公司设有产品零备件仓库,长期提供备件及相应的售后服务,买方提前以传真形式书面通知卖方,卖方提供的设备配件保证是原厂正品的配套件,卖方应及时回复买方供货时间、费用的情况,并在收到买方有效付款凭证后,保证在的48小时内发货,以保证用户使用。

8. 卖方每月对设备进行一次售后跟踪,进行客户回访,及时沟通解决买方在使用中的问题 。客服电话:

9. 买方对卖方售后服务人员因服务质量或不合理收费有意见,可以直接向卖方投诉,卖方应在一个工作日内予以答复!投诉电话:010-56802091

HXP-F recycling cycle sandblasting machine technical note

I. Purpose and Characteristics

HXP-F recycling cycle sandblasting machine has no dust pollution during the blasting operations, protecting the health of workers to be in line with national environmental requirements. It is mobile and flexible, widely used in machinery, ships, bridges, railways, oil pipelines, boilers and port construction industries for superficial dust abatement, surficial hardening of steel structure; and the superficial carving of leather, clothing, glass, stone etc.; reroute change construction of the traffic routes and decorative treatment of fountains.If using the machine for sand blasting,don't need to build sand blasting room.

II. Technical parameters

Technical parameters

Sandblasting part overall dimensions:Φ600×1434

Recycling part overall dimensions:L1700×W700×H2000

Power supply:380V,50Hz

Power:7.5kw

Pressure of work:0.6-0.7MPa

Surface treatment level:Sa2.5-3

Gas consumption:2.2-6m3/min

Sand blasting efficiency:6-15m2/h

The abrasive volume:(Volume is associated with tank diameter)

| Diameter (mm) | 600 | 700 | 800 | 900 | 1000 | Because of differences in material density, loading capacity data is for reference only

| |

| Volume(m 3 ) | 0.18 | 0.3 | 0.46 | 0.63 | 1 | ||

| Loading quantity kg | Brown fused alumina | 351 | 585 | 897 | 1229 | 2458 | |

| Silicon carbide | 300 | 500 | 760 | 1046 | 2092 | ||

| Steel shot | 801 | 1335 | 2047 | 2800 | 5600 | ||

| Quartz sand | 306 | 475 | 629 | 850 | 1700 | ||

III. Working principle

Source of pressurized air goes into the intake port, the air sprays from the spray gun after regulation, attracting abrasive material into the spray gun, forming a high-speed abrasive airflow to beat against the workpiece.

Vacuum suction pump forms the vacuum, sucking back the discharge of abrasive material flow. Abrasive material flow is separated in the cyclone for the first time, leaving available abrasive material; dust flow entering into the dust tube for the second separating, dust is separated out, through filter pump the clean air is sucked into the vacuum pump before into the atmosphere.

IV. Procedure

Check the appearance of the machine that should be in good condition, and all parts should be connected securely, the filter is without damage. By adding the abrasive material into the sand can through the mesh with an amount not less than 40 kg, and then tighten the knob on the cyclone. The spray gun can also be used for sand suction.

Connected to the gas source, opening the valve, starting the vacuum pump, and you shall feel the gun is sucking a large number of inhale in the mouth. Adjusting the vacuum filtration pair to the appropriate working pressure.

Handing the spray gun, letting the brush head be close to the surface of the workpiece, pressing the switch on the gun, which has began blasting, regulating the valve to the best sand for blasting effect. During the work process, you must always keep the brush head flat against the workpiece surface with uniform movement, but not allowed to leave.

Depending on different surface roughness, replacing different types and sizes of abrasive material; replacement brushes of different shapes for processing exterior angle and circular shapes such as artifacts.

The sand tubes, trachea and recovery pipe shall be straight and flat as possible with less bending, so as not to affect the results of the sand.

After finishing work, releasing the switch on the spray gun, do not immediately raising the gun to ensure abrasive spray is fully recycled. Finally, close the valve and disconnect the gas source.

The separation level between the abrasive material and dust can be adjusted, open cyclone, there is a block dust plate, by replacing dust plates of different sizes, the size of the separated dust particles can be adjusted. The larger dust plate is, the greater separated dust particles; the smaller dust board, the separated dust particles is smaller.

V. Routine maintenance and repair

1. After each work, the gas source should be shut, wiping clean the machine. If the machine won’t be used in a longer period of time, the abrasive material in the sand can and dust inside the barrel should be cleaned to avoid compaction.

Cartridge top has the rapping device, regularly passing into it with the air for cleaning the floating ash on the filter surface.

2. The dust in the dust barrel should be promptly cleaned after each work shift.

VI. Common faults and exclusion

1. No sand or poor sand:

Adjustment of the sand valve and the sand tank bottom at the inlet end of the gap nut. If there’s still no outlet of the sand, you should check the sand and the sand pipe valve to see if there is blockage or any breakage.

Check the spray gun nozzle to see whether it is in normal jet, and the trachea is blocked.

2. Poor recycling results:

Check whether the system has leaks where the filter is being severely blocked, check whether the vacuum pump is working properly.

3. Dropped efficiency:

Check whether the gas supply source is adequate.

After using for a period of time, the processing efficiency drops, you should check whether the blasting nozzle diameter is in excessive wear, resulting in insufficient gas supply, pressure drop, replace sand mouth of T11.L08.02.

(北京市胶辊、玻璃辊、压花辊专用喷砂机厂家)

供应胶辊、玻璃辊、压花辊专用喷砂机厂家批发价格